Every product you launch competes on more than just function—it competes on formulation clarity, label compliance, and sourcing reliability. And when you’re managing multiple SKUs, tight timelines, and global ingredient lists, even a minor raw material issue can create weeks of delay.

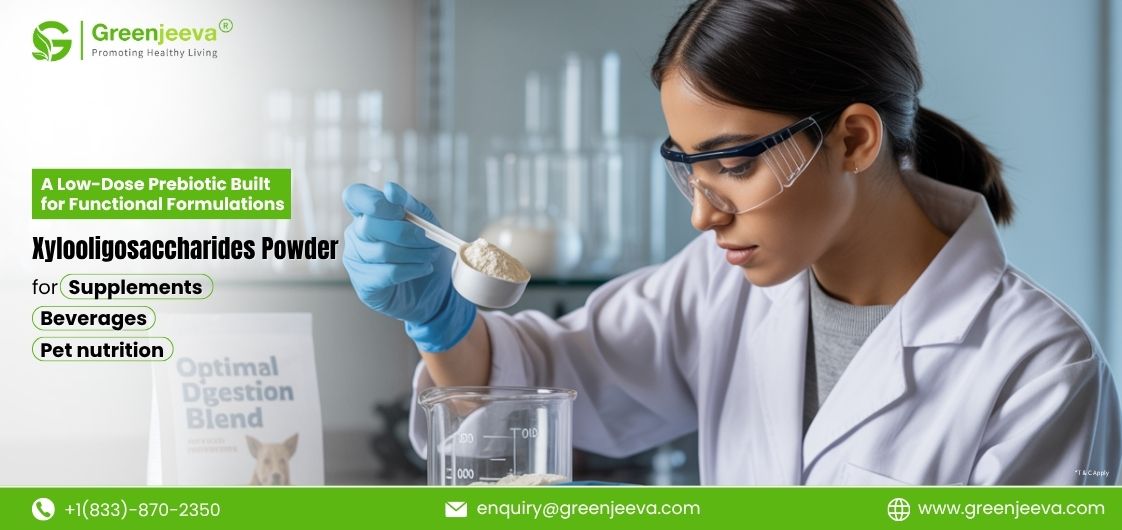

That’s exactly why more manufacturers are turning to prebiotics likeXylooligosaccharides Powder—not just for what it adds on the label, but for what it doesn’t disrupt in the process. It works cleanly. It blends easily. It doesn’t force reformulation downstream.

If you’re evaluating fiber inputs for functional foods, dietary supplements, or pet nutrition, this prebiotic deserves a closer look, especially if your team is working toward cost efficiency, quality control, and low-risk formulation behavior at scale.

Let’s break down what makes it work and what you need to know before you source it in bulk.

Xylooligosaccharides Powder is a food-grade prebiotic fiber derived from lignocellulosic biomass such as corncobs or hardwood.

It contains short-chain xylose units that are not digested in the upper gastrointestinal tract, making it suitable for gut-focused formulations in both human and pet nutrition sectors.

This industrial-grade prebiotic is typically processed through enzymatic hydrolysis to ensure high purity and stability. Clean-label formats are available, often complying with Non-GMO, allergen-free, and food-safe standards, ideal for use in functional food, beverage, and nutraceutical formulations.

Xylooligosaccharides Powder functions as a low-dosage fiber that integrates seamlessly into various applications without altering taste or texture.

Its properties make it suitable for multiple product types:

- Functional beverages: pH- and heat-stable, making it effective in pasteurized or shelf-stable drinks.

- Nutraceutical powders and capsules: Neutral taste and low hygroscopicity simplify handling and blending.

- Snack bars and cereals: Enhances moisture retention and fiber content.

- Pet nutrition: Often used in companion animal products to support gut-related functions.

Because of its compatibility with other ingredients and clean-label positioning, Xylooligosaccharides Powder is now a preferred prebiotic ingredient for supplements and ready-to-mix formulas.

Manufacturers value Xylooligosaccharides for its formulation efficiency, supply chain readiness, and performance in real-world processing environments.

Key formulation and industrial advantages include:

- Low inclusion rate: Effective at concentrations as low as 1-2%, reducing cost per batch.

- Thermal and pH stability: Withstands standard processing conditions in beverage, baking, and extrusion applications.

- Sensory neutrality: Doesn’t affect color, taste, or odor, offering flexibility in flavor-sensitive formulations.

- Regulatory recognition: Typically considered GRAS and compliant with food-grade production norms.

Its performance in formulations allows developers to support fiber claims without compromising product integrity.

North America continues to see a steady rise in demand for clean-label, functional prebiotics like Xylooligosaccharides Powder across multiple product categories.

The increased use is driven by:

- R&D interest in gut-supportive ingredients for functional foods and supplement systems.

- Growth in pet nutrition formulations that emphasize digestive function and ingredient transparency.

- Shift toward label-friendly fiber sources to meet consumer preferences.

This demand is reflected in procurement patterns, with more sourcing teams seeking bulk Xylooligosaccharides Powder at wholesale pricing to meet expanding production needs.

Quality assurance starts with supplier selection, documentation verification, and understanding the product's specifications.

Procurement managers and sourcing heads should verify:

COA and MSDS for Xylooligosaccharides that clearly outline moisture content, mesh size, purity level, and microbial count.

- Certifications such as Non-GMO, allergen-free, kosher, or ISO-compliant manufacturing.

- Heavy metal and pesticide residue testing to comply with food safety norms.

- Batch-level documentation for traceability and audit readiness.

- MOQs for bulk Xylooligosaccharides that align with pilot or full-scale production volumes.

Choosing a bulk supplier who understands formulation priorities and regulatory expectations is essential.

A reliable bulk Xylooligosaccharides Powder supplier offers consistent quality, technical documentation, and scalable inventory.

Key attributes include:

- Ability to supply food-grade Xylooligosaccharides in packaging suitable for industrial environments.

- Access to wholesale priced Xylooligosaccharides Powder with flexible volume tiers.

- Readiness to provide documentation for bulk ingredient sourcing such as COA, MSDS, allergen statements, and country of origin.

- Familiarity with formulator expectations for moisture content, particle size, and sensory consistency.

A streamlined supply chain—from sampling to documentation—helps reduce formulation risk and downtime.

Xylooligosaccharides is known for its thermal and chemical stability, making it suitable for a range of processing environments.

It remains stable:

- Under heat: Suitable for extrusion, pasteurization, and spray drying.

- Across pH ranges: Maintains structure in acidic beverages (as low as pH 3) and neutral foods.

- In dry blends: Low moisture absorption reduces caking, improving shelf life in powder formats.

These traits contribute to dependable functionality across product formats and long-term storage.

R&D professionals are leveraging Xylooligosaccharides to address formulation challenges related to clean-label claims, fiber content, and compatibility with other functional ingredients.

It’s often included in:

- Formulas alongside other plant-based fibers and extracts

- Prebiotic blends for functional beverage powders

- Gut-friendly pet nutrition mixes

- Low-dose fiber systems in capsules and tablets

Its ability to perform at low inclusion levels without requiring formulation overhauls makes it attractive during prototyping and scale-up.

Strategic sourcing of Xylooligosaccharides Powder begins with aligning technical specs to production needs and verifying supplier documentation.

Before procurement:

- Define your required purity levels (e.g., 70%, 95%)

- Confirm delivery timelines and warehousing logistics

- Clarify MOQ and available sampling for internal evaluation

- Review regulatory and export readiness if products will be shipped internationally

A sourcing strategy focused on documentation, consistency, and application fit reduces risks for both pilot and full-scale production.

Xylooligosaccharides Powder isn’t just another fiber; it’s a strategic input that meets the technical and operational standards modern formulations demand. From low inclusion rates and neutral sensory profile to compliance-ready documentation and processing stability, it’s built for efficiency across product categories.

For procurement teams and formulators balancing performance with supply chain predictability, it offers a rare combination: clean-label compatibility without added complexity. Whether you're scaling a nutraceutical line or fine-tuning a functional food blend, understanding how to source it right makes all the difference.

Green Jeeva supplies food-grade, industrial-scale Xylooligosaccharides Powder to manufacturers across functional foods, supplements, and animal nutrition sectors. Our inventory supports a wide range of documentation needs, and our sourcing teams are equipped to help you plan production with COA, MSDS, and bulk packaging ready on request.

Reach out today to order samples, specifications, or to discuss your MOQ requirements.

**The Food and Drug Administration has not evaluated these statements. This product is not intended to diagnose, treat, cure, or prevent any disease.**